Have espresso machines become more environmentally friendly?

As climate change hits coffee yields, a small number of espresso machine manufacturers are helping cut emissions on the consumer side. Jess Palmer speaks with Carimali’s marketing manager, Roberto Gregis, to find out how.

With unprecedented heat waves, forest fires, and droughts affecting countries around the world, we no longer need a climate scientist to tell us: the buildup of carbon in the atmosphere can have devastating effects on the environment.

However, while climate change is affecting the entire planet, few industries are more at risk than coffee. Studies show that 50% of the land used to grow high-quality arabica coffee may be unproductive by 2050 due to climate change. This number could increase to as much as 88% for coffee farms in Latin America.

Each stage of the supply chain adds to the total carbon footprint of a cup of coffee, from cultivation to consumption. Notably, coffee production is estimated to claim the largest carbon footprint in the coffee supply chain, due to the energy, water, and land consumed.

After production, consumption is considered to be the second-largest contributor to coffee’s carbon footprint. By some estimates, the preparation and consumption of coffee account for nearly a third of total carbon emissions, playing a significant role in its impact on the environment.

In the past, espresso machines were one of the main culprits. But as manufacturers become increasingly aware of how their equipment contributes to climate change, a number of innovative brands have taken steps to provide environmentally friendly alternatives.

The problem with traditional espresso machines

Using a traditional espresso machine is considered to be among the most carbon-intensive activities in the journey from seed to cup.

The majority of traditional espresso machines contain a boiler that heats between 1 to 2 litres of water. When the machine is on, the boiler helps to maintain a high water temperature and create steam. However, this water is not used to create shots of espresso.

Most machines also contain a thermal syphon system which will draw in fresh water and push it through a contained tube within the boiler. It is this system that supplies hot water to the group heads to make espresso.

Typically, the energy used by traditional espresso machines is between 12kWh and 50kWh per day. Additionally, a machine that is used infrequently uses more energy per cup of coffee, due to the energy needed to keep the water at a stable temperature.

Studies show that traditional espresso machines used sporadically can consume more energy per year than the average home in the UK. In some espresso machines, an inadequately insulated boiler can waste up to 50% of energy as the heat simply escapes.

It is estimated to take around 0.0156kWh of energy to produce a double espresso. However, this only represents a small proportion of the energy used for most coffee drinks, as 65% of consumers tend to take their coffee with additional ingredients, such as milk or cream.

Recent research shows that adding steamed dairy milk to coffee is considered one of the most significant carbon contributors.

Towards an energy-efficient future

With global coffee consumption on the rise, new technologies have made the process more energy efficient.

One such advancement is the use of induction heating in espresso machines. This boiler-free system can channel either water or milk through metal tubes, which are surrounded by electromagnetic induction coils.

These coils can heat liquid within seconds, negating the need to keep large volumes of water warm throughout the day.

Additionally, the introduction of motion sensor machinery tackles the problem of idle machines or those in “sleep mode”, which still consume large amounts of energy.

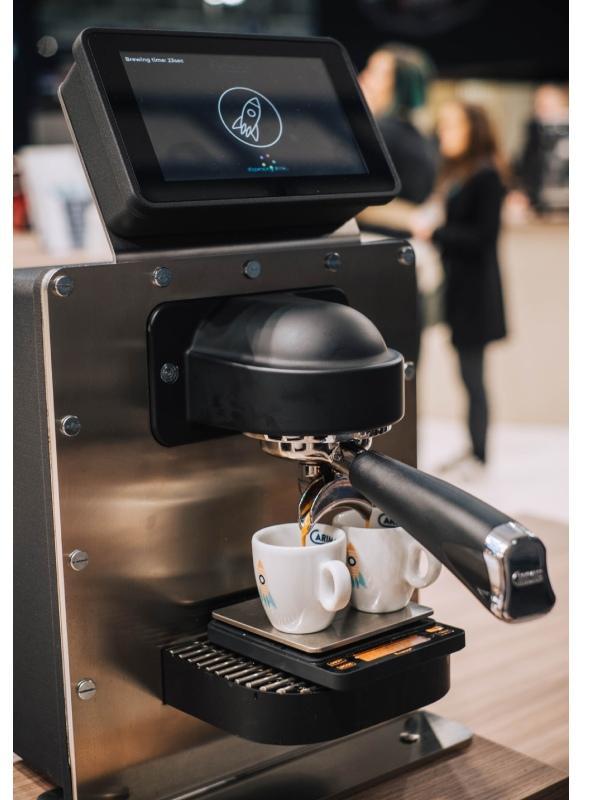

Italian espresso equipment maker Carimali is championing both induction heating and motion sensors in their machines to combat energy waste.

Roberto Gregis, the marketing manager at Carimali, explains how the motion sensor technology works.

“As soon as a user gets within 70cm (2.3ft) of the machine, it automatically starts the heating process,” says Roberto. “This way, the machine only heats water when necessary.” Overall, motion sensor technology may be able to reduce a business’s energy costs by up to 30%.

Another key point in reducing the carbon footprint of coffee is the growing popularity of plant-based milk alternatives. Studies show dairy milk contributes more to climate change than any other type. Notably, switching from dairy could save as much as 35% in carbon emissions.

A wide range of dairy-free, plant-based alternatives are available. However, oat milk has been hailed as the most environmentally friendly way to consume milk.

The majority of traditional espresso machines can steam all types of milk with ease. That said, one of the most effective ways to reduce carbon emissions would be to combine energy-efficient machines with plant-based milks.

While converting to an energy-efficient setup may seem daunting, changes like these can help safeguard the future of coffee and the millions who rely on it for their livelihoods.